Happy December everyone. The blog has seen a quiet spell during most of October and November, but this hasn’t been a reflection on the Flux Cap’s progress. Oh no. On the contrary the little yellow peril has changed a load since arriving back at Tim Glover’s Road House Motor Co. Here’s the update…

The goal was to get the rolling Enfield almost (externally, at least) complete and on display for Adrian Flux insurance at the NEC Classic Car show in November. We did it, but it was down to the (electrical) wire. I pushed it into the display hall at 9.57pm on Thursday night, just as the Tannoy announcement crackled: ‘The display halls are now closing, so could everyone please leave their cars and make their way to the nearest exit’. I had B.O that day.

Three big days and long nighters with Road House’s Tim got the car to that stage. Pizza and beer was instrumental in the process.

Tim finished machine polishing the bodyshell and hung the bonnet/boot on.

He then set to work aligning the doors, which wasn’t as simple as expected, because this was never a precision-built stamped-out bodyshell. It was a completely hand-beaten low-volume bodyshell, which meant panel gaps were rarely as consistent. Nevertheless, Tim is a total perfectionist and won’t let the Enfield leave his workshop until he’s done his absolute best. Cheers Tim, the result looks cracking. And sorry for the late nights.

Whilst Tim assembled the (Hillman exterior, Morris interior) door locks and drenched the inside cavity with waxoyl before fitting the interior trim panels (notice the previous owner(s) had fitted door impact bars! I went off to a place called Woolies. This is an Aladdin’s cave for all the stuff you need when restoring a classic car but don’t know what it’s called or where it can be found. My shopping list at Woolies was for new door rubbers, window seals and felt weather stripping.

BYE GLASS, HI LEXAN

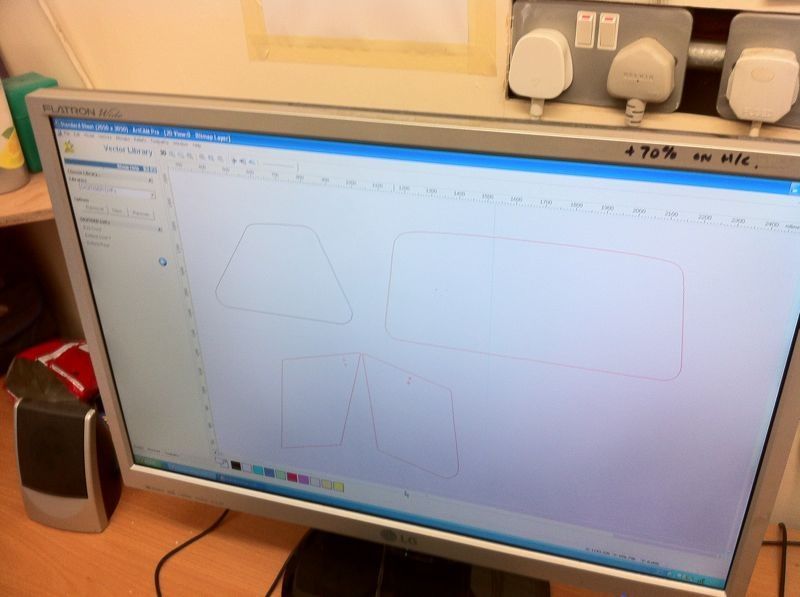

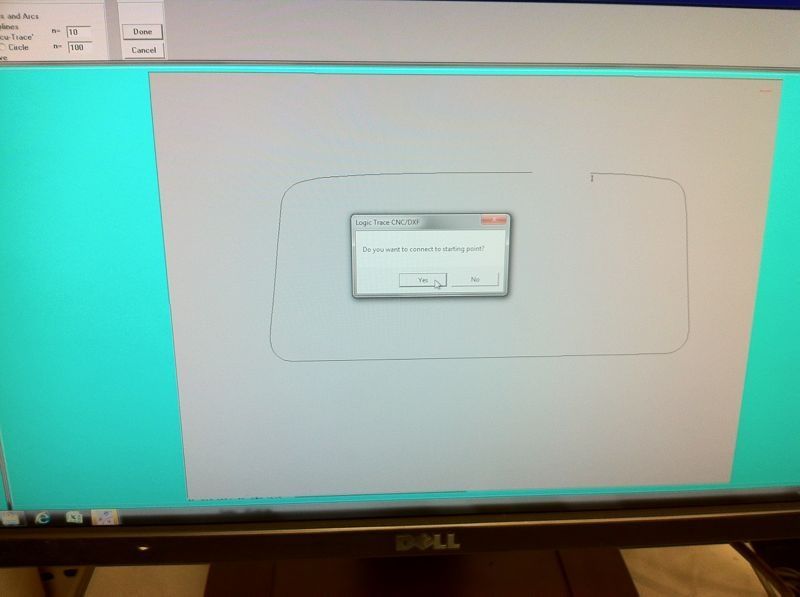

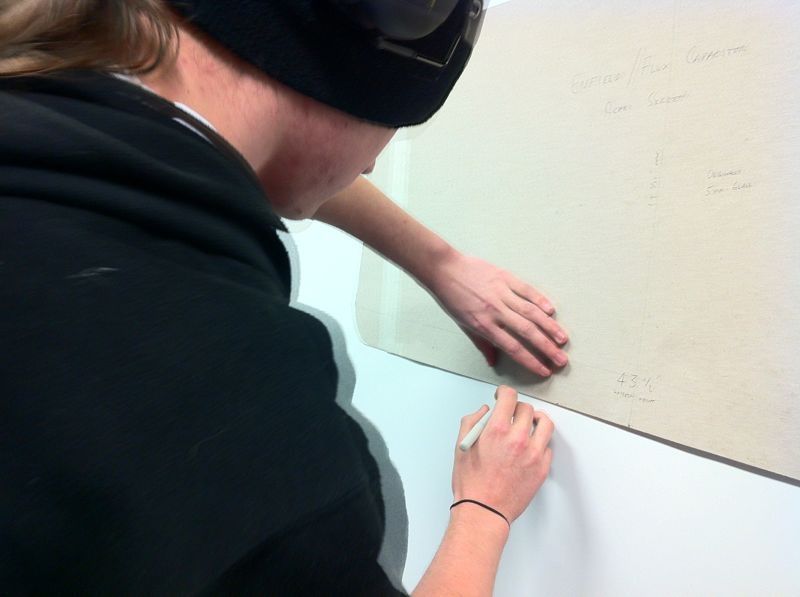

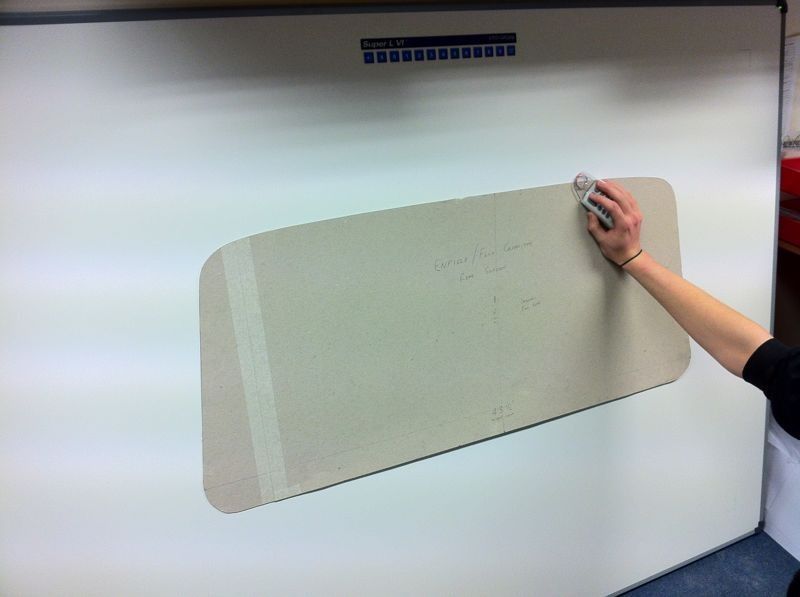

Back at the workshop we unwrapped and fitted up the Lexan sliding driver/passenger windows made by Plastics 4 Performance in Bolton. Less than two weeks ago I’d laid the original glass down onto paper and drawn out templates. These were posted off and then the Plastics 4 Performance guys could set to work digitizing my pencilled templates.

Normally they would 3D digitize curved glass and form them in an oven, but bar the windscreen the Enfield has all flat glass. I’ll be having a Lexan windscreen made sometime next year. More on that in a tick.

Â

Visually they look identical to glass, but the weight difference is remarkable. The fact they are virtually unbreakable is also kinda useful on a race car. I opted for a pre-coated Lexan sheet, which is scratch resistant and anti-fog. Apparently this is the same spec stuff as used on British Touring cars. The new ones arrived swaddled in acres of bubble wrap. That’s my back window that is.

I wanted to use the same window rubbers with a chrome strip as per the original, but these thick extrusions ended up becoming a headache to work with, especially in a cold wintry workshop. Sore finger tips and hours later, we wrestled them into place.

Â

Â

Â

Â

All that was left then was the dreaded task of fitting a 37-year old totally obsolete and ruddy priceless windscreen. It took three hours but Tim got it back in with a ton of profanities, but without any cracky bits. We’ve even retained the original Ozone Friendly sticker.

Â

Â

It will be amazing to have a Lexan duplicate made in 2013, but I’m not sure my heart can cope with the stress of removing the original again. According to the Enfield buffs at the BVS (Battery Vehicle Society) the value of one of these cars hinges on whether the windscreen is intact.

MMM, STICKERS

I must give Pete at Black Cat Race Graphics a plug, because he went above and beyond the call of duty to get some sponsor decals sorted for the Flux Cap (npower, Adrian Flux Insurance & Red Maple IT consultants). Not only that but he stayed up half the night helping out with other odd jobs on the car to get her looking finished for the NEC show.

Â

Â

So what’s happening next? Down to www.currentracing.co.uk in Hungerford for the wiring and control unit (EV ECU brain). These guys still hold the record for the world’s fastest full bodied EV, and they’ve been kind enough to let me use their years of r&d within electric drag racing to start the Flux Capacitor’s heart beating. Exciting times, as the finish line of this project seems to be within sight.