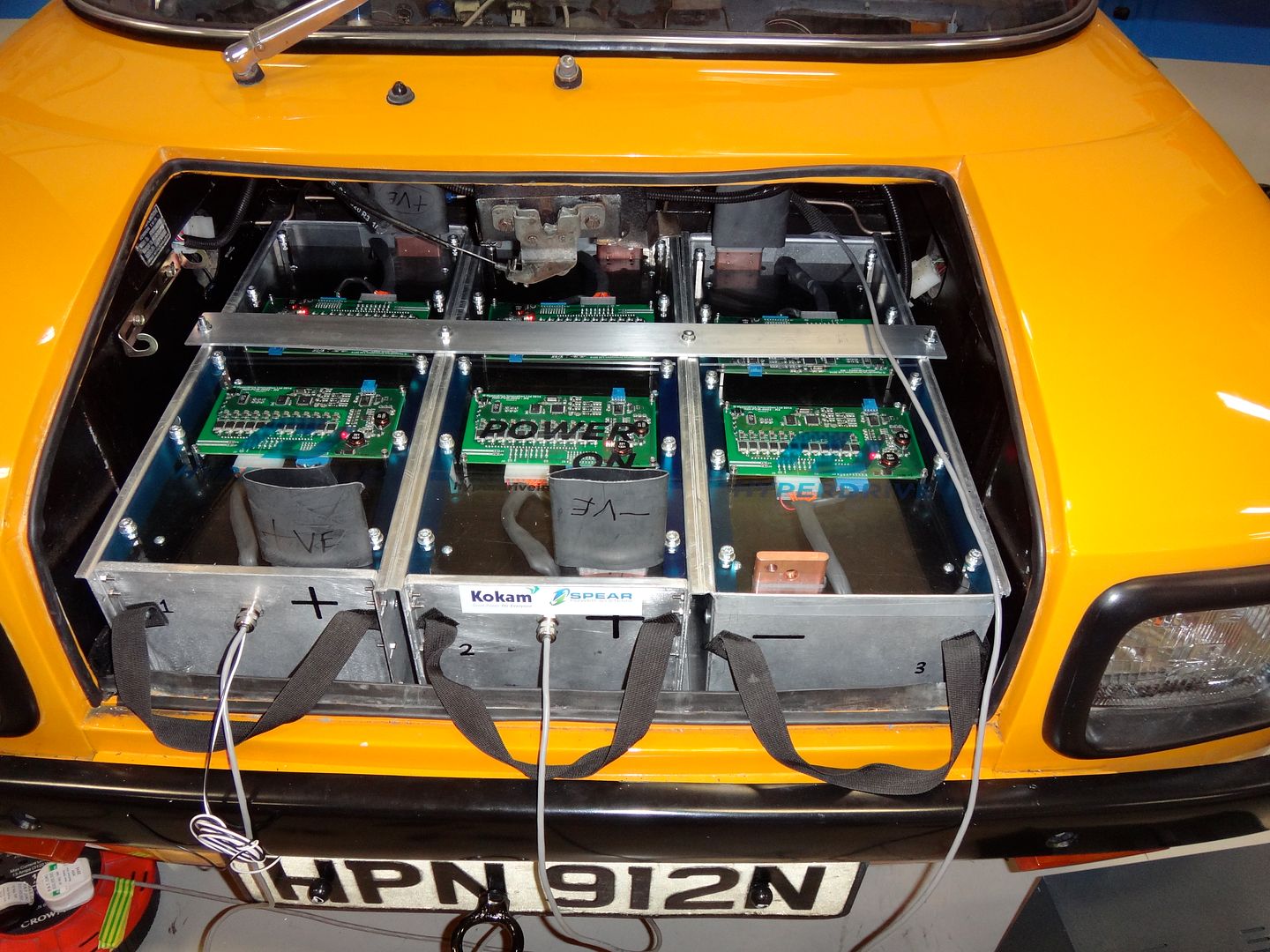

Fiiiiiiiiiiiiiiiiinally. Here is the completed battery pack for the Flux Capacitor as made by Hyperdrive Innovations using Kokam lithium-ion cells.

Last blog I tried to show the immense effort taken to build batteries capable of delivering 370 volts, 600kW, 2000+ amps, 1003hp, 1100lbft that weigh less than 150kg. Well, here you go. I still can’t compute the stats when I stare at this strange electrical package.

To recap, this is 144 Li-MNC 30 amp 4.2v pouch cells in total, carefully packaged (vertically stacked) into three aluminium enclosures; 2 in parallel and 1 in series. The military grade cells were shipped over from Kokam in Korea, who have put a value of $80,000 on them. Yeah, $80k. And that’s without the Hyperdrive custom battery management system.

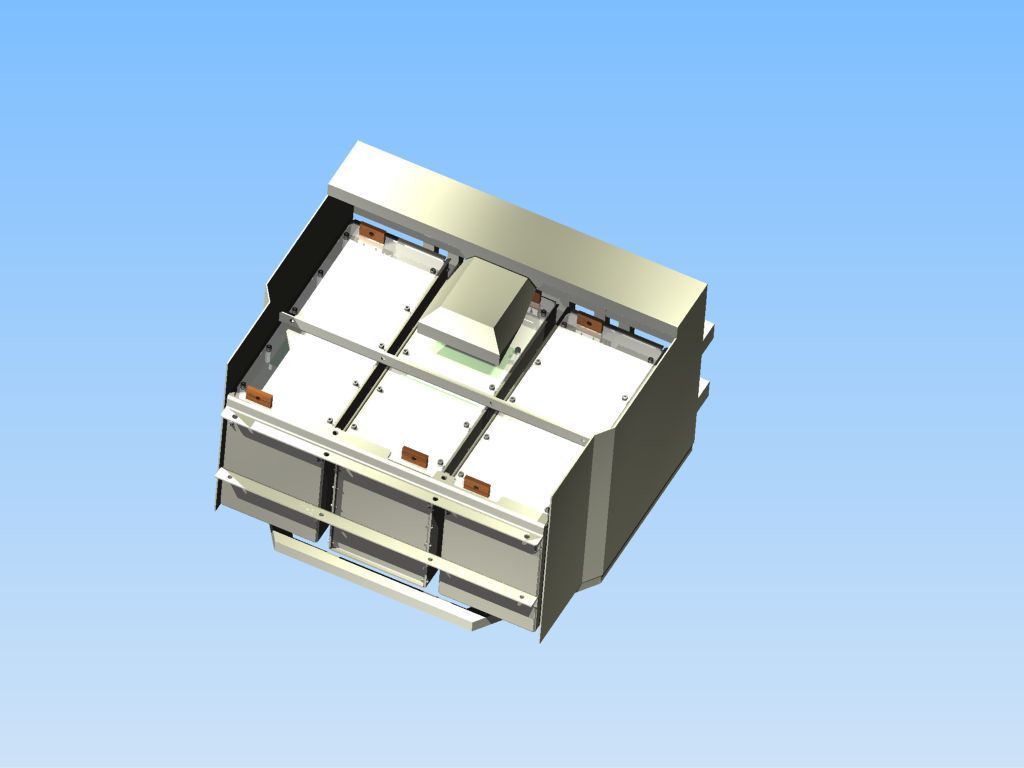

It started as a design on a computer screen like this…

…and has ended up like this. Neat. Potent.

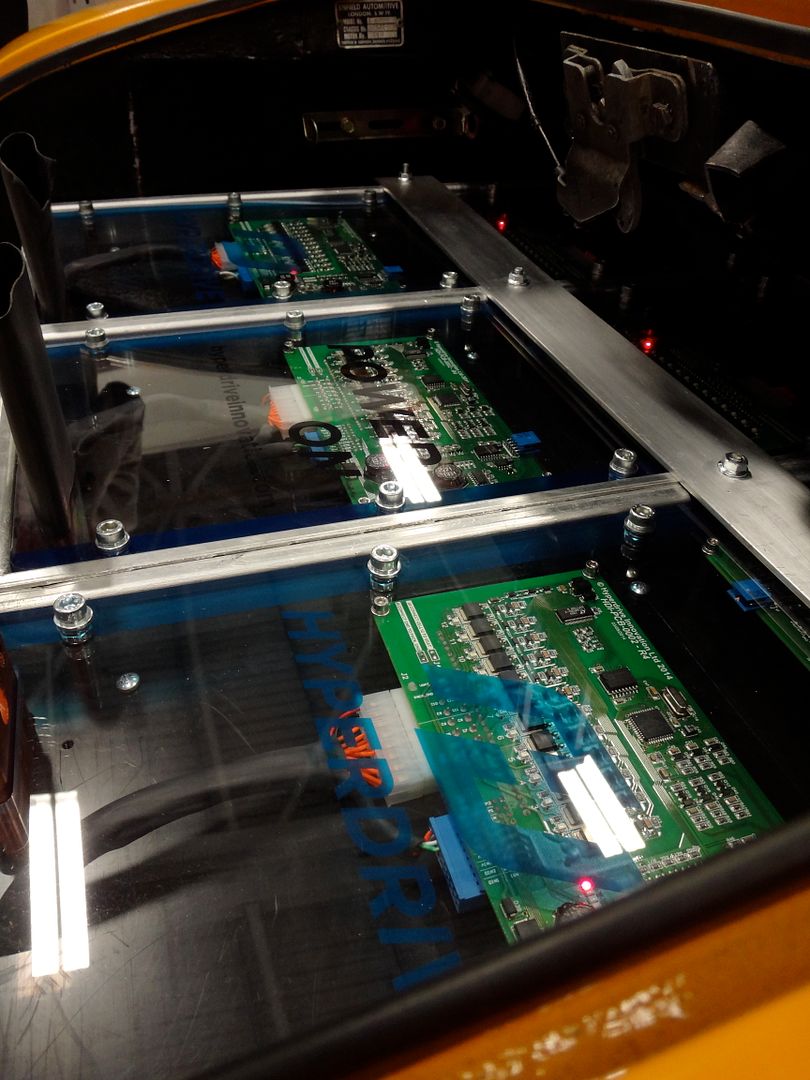

Through the Perspex tops of the battery enclosures you can see the circuit boards of the BMS (Battery Management System), which is designed to effectively mother and discharge all 144 cells equally. It will also alert us to any faulty cells.

Hyperdrive Innovation’s Robin Shaw showed me on his laptop the state of the battery packs and how their BMS is critical for ensuring the li-ion pack never runs too low on charge, which can cause irrepairable damage. And believe me, we don’t want that after taking so long to source these sacred ex-military helicopter gunship cells.

There is an on-board fire extinguisher system in the boot (it was the only location large enough, and it worked out well for weight distribution), but really this is a last resort. Once deployed it will destroy the function of the batteries.

The team at Hyperdrive in Sunderland have made possibly the hardest jigsaw piece fit in the Flux Capacitor’s puzzle. With battery pack sorted, it was time to take the car back down to Stamford for a few tweaks before its baseline.