My brother Greg and me are close mates. For the first time in years we live close to one another, which means we’re trying to find spare evening time to bond in sheds over spanners and cider.

Greg restores pre-war Bentleys for a living and has been largely responsible for my adoration and respect of old vehicles. He’s always loved vintage Brit stuff for fun and ’90s German stuff for commuting work. He lent me £250 back in 1998 so I could buy a second car to use for commuting – eventually trading my way up to bigger and better things than the battered smoky VW Bay window panel van I started with. Thanks bro.

So what’s the latest on the Enfield?

Well, things have been delayed. For almost six months I have been awaiting the production of a specific type of lithium-ion battery pack for the car, which has definitely been the hardest challenge. Without the correct batteries the Flux Capacitor simply won’t give the acceleration performance I need. Up until now the projected cost of these has been utterly crippling, and many tests of sample batteries have proved them to be inappropriate. This is where I wish I had Lord Drayson’s wallet.

The type of li-ion cells I require are not designed for normal commuting. Because the Flux Capacitor’s main focus is to be a drag car, the challenge we face is to allow a massive discharge of power in short space of time (under 15 seconds). I am less interested in battery range, but more short-burst sheer performance.

The Aim? Enough high ‘C’ rated batteries to herald 378-volts and up to 1800amps. The modern battery packs will weigh something like 75kg compared to the original car’s 300kg lead acid lumps.

I have been holding out to negotiate a deal with a specialist battery manufacturer, which hasn’t been easy as most of them don’t entirely understand my eccentric one-man EV quest. If anyone can help please don’t hesitate to get in contact.

ANYWAY, ABOUT MY BROTHER…

Whilst waiting for the word on batteries Greg pointed his can of cider at the yellow ochre wedge and said ‘It’s a 2-seat city car designed in the early ’70s to do 40mph and 0-30 in 12.5 seconds. It was never supposed to go 60mph, let alone 100+mph. It’s not even 10-foot long for f***’s sake Jonny. At least make sure it’s tight and steers right’.

His wise words struck a poignant chord. On the drag strip it might get a little frisky, and so I don’t want any play in any suspension or steering parts.

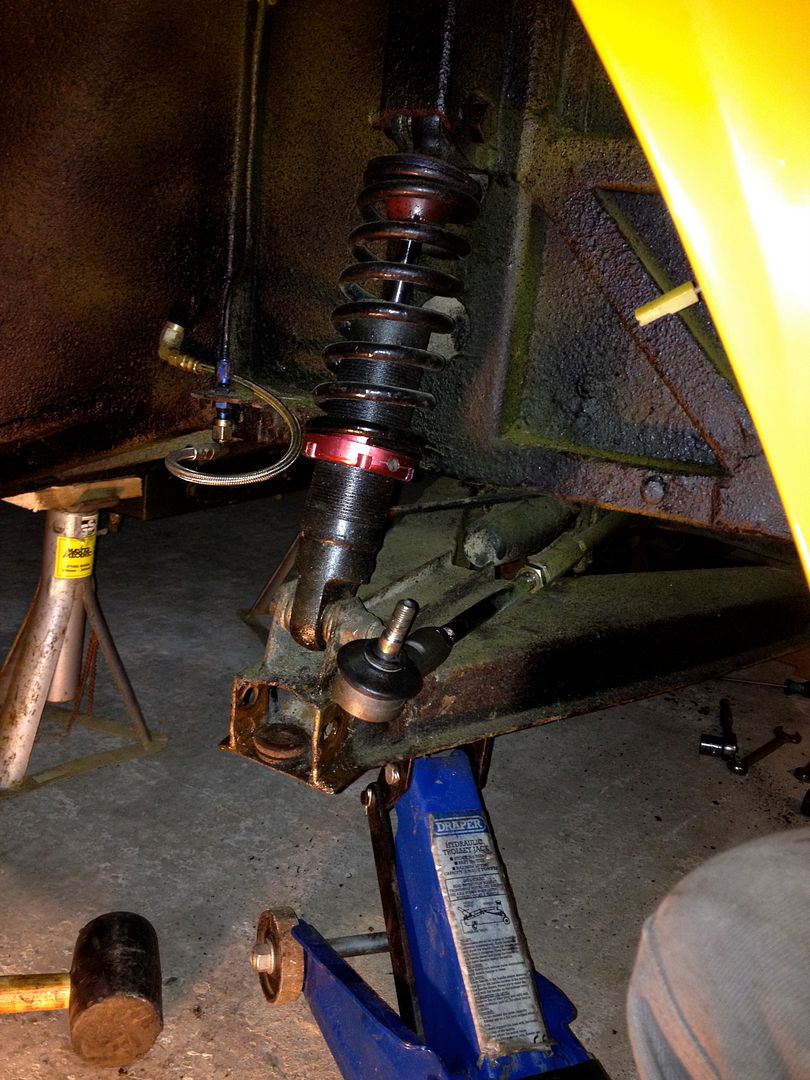

And with that we put it on axle stands and pulled the whole front end off. None of the [mostly Hillman Imp] suspension assembly was particularly worn, but Greg’s pearls of wisdom were exactly that.

Off came the Imp A-arm wishbones, which the Enfield factory had reinforced with extra boxing to cope with the 300kg of lead acid batteries.

Greg in rare smiling moment. He secretly loves working on cars with seized bolts. He swore less because I’d invested in some compressed air tools…

The steering rack is also Imp but seems fine. I replaced the track rods and ends with new items (mk2 Fiesta conversion – see an earlier blog for this).

And the oh-so-sexy BG Developments custom machined AP calipers, discs and carrier brackets had to come off. Again. If making old electric cars go fast was easy then everyone would be doing it, right?

Stub axle all off. The AVO coilovers are all new so they are fine.

The wishbones were sent away for blasting and powder coating.

The kingpins are the key component for a play-free front end. They are Mk2 Hillman Imp items on the Enfield and I decided to farm them out to be refurbished. Weirdly, the two most respected Hillman Imp specialists in Britain are based five miles from my house and five miles from my parents’ house.

A huge thanks then to Ian and Trudy Toon at Competition Classics (01780 756450) in Stamford for bursting with Imp enthusiasm, and for flawlessly reconning my kingpins. Don’t they look prurrdy?

I bought new bearings from Ian Toon and ordered a set of urethane bushings from SuperFlex. In the next fortnight this lot will be bolted back up and I’ll attempt to do the basic tracking.

Next? It’s time to trailer the Enfield up north to Newcastle where the BMS (Battery Management System) and, all boding well, battery packs will be fitted up in this space by British EV experts Hyperdrive Innovations.

Thanks again for reading the blog. More to come very soon. All boding well we plan to have the little lello peril out on track for some shakedowns this July…